Why calibrate?

Calibration consists of defining and checking through a test – on a representative sample surface – that spraying conditions

(nozzle height, walking speed) are observed, in order to be more precise and efficient.

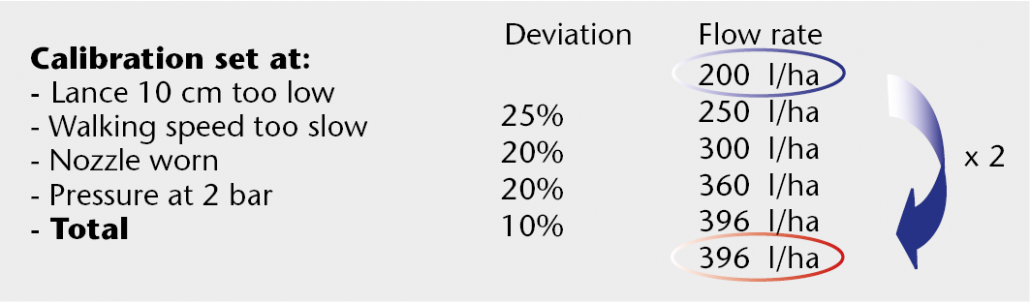

Deviation from ideal conditions can result in significant performance differences, and increased product use:

To avoid pressure variations, we recommend the use of a control valve or regulator: integrated in the SERIES 2000, or available as an accessory.

How to calibrate?

We recommend calibrating your spraying speed at least once a year.

1 – Check that the sprayer operates correctly and safely and the nozzle height to get the required treatment size.

2 – Define a surface area test similar to the nozzle coverage.

3 – Fill your sprayer with water and spray according to the required conditions (nozzle height and walking speed) on a defined area, for example 100 m².

4 –To calculate the volume rate (l/ha), multiply the sprayed quantity (missing from the tank) by 100.

Example:

If 3 litres have been sprayed on 100 m2, your volume rate is :

3 x 100 = 300 l/ha.

For a quick and reliable reading of the quantity sprayed on the test, use the KALIBOTTLE

to calibrate your sprayer. (see calibration table attached)

Sprayer maintenance and calibration :

All sprayers require basic maintenance after each use and also a basic service at least once yearly. For an easy guide to sprayer maintenance please use the National Sprayer Testing Scheme (NSTS) checklist as a guide.

You can download this file here : National Sprayer Testing Scheme (NSTS) checklist